Provenance Merino

Our first fully traceable wool – October update

The production of our first ever fully traceable merino wool is starting to gather momentum.

Next comes the spinning where carded wool is transformed into spun yarn ready for weaving. Here twist is added and the yarn is drawn out to ensure the correct yarn count. You can see the winding process and the preparation for pre-twisting. Yarn runs through clearers to remove any faults or imperfections that may be present after spinning. Finally the yarn is assembled ready for winding onto twisting bobbins and then placed on the up-twister where the correct ply twist is inserted onto the yarn. Unbelievably this cycle has already taken nearly 10 months. There are just a few more processes to go before we are finally ready to start sewing.

Carding

Spinning, winding and twisting

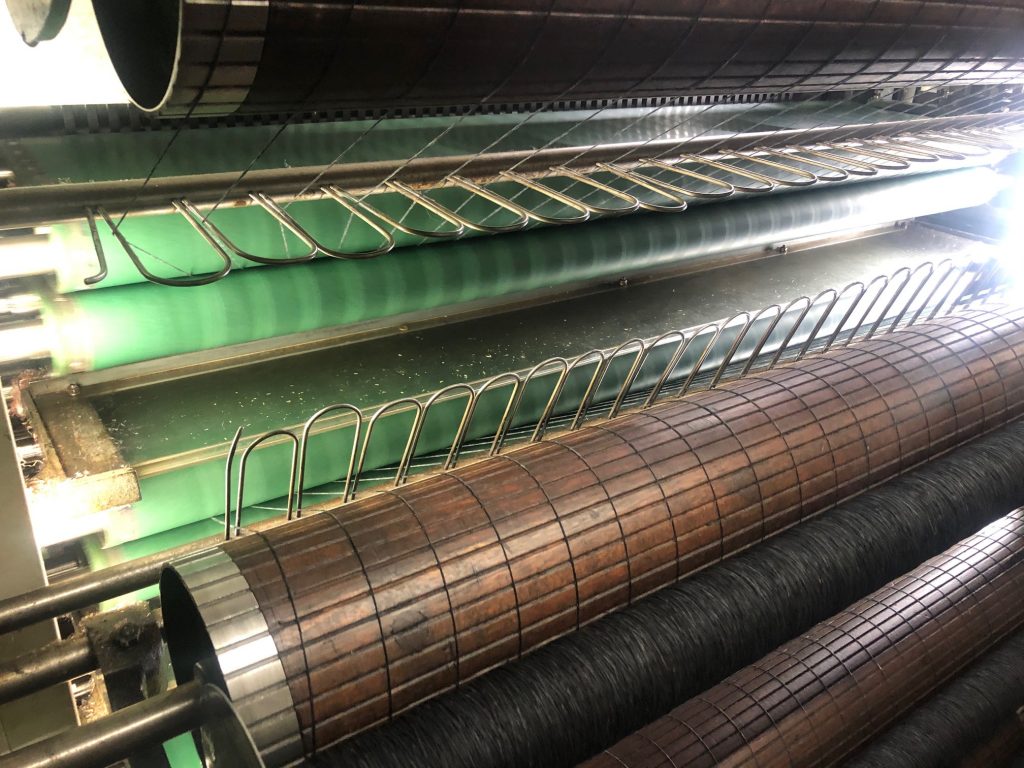

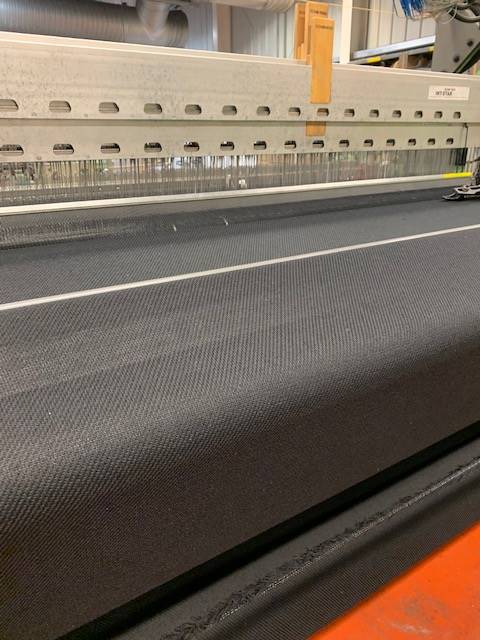

Weaving

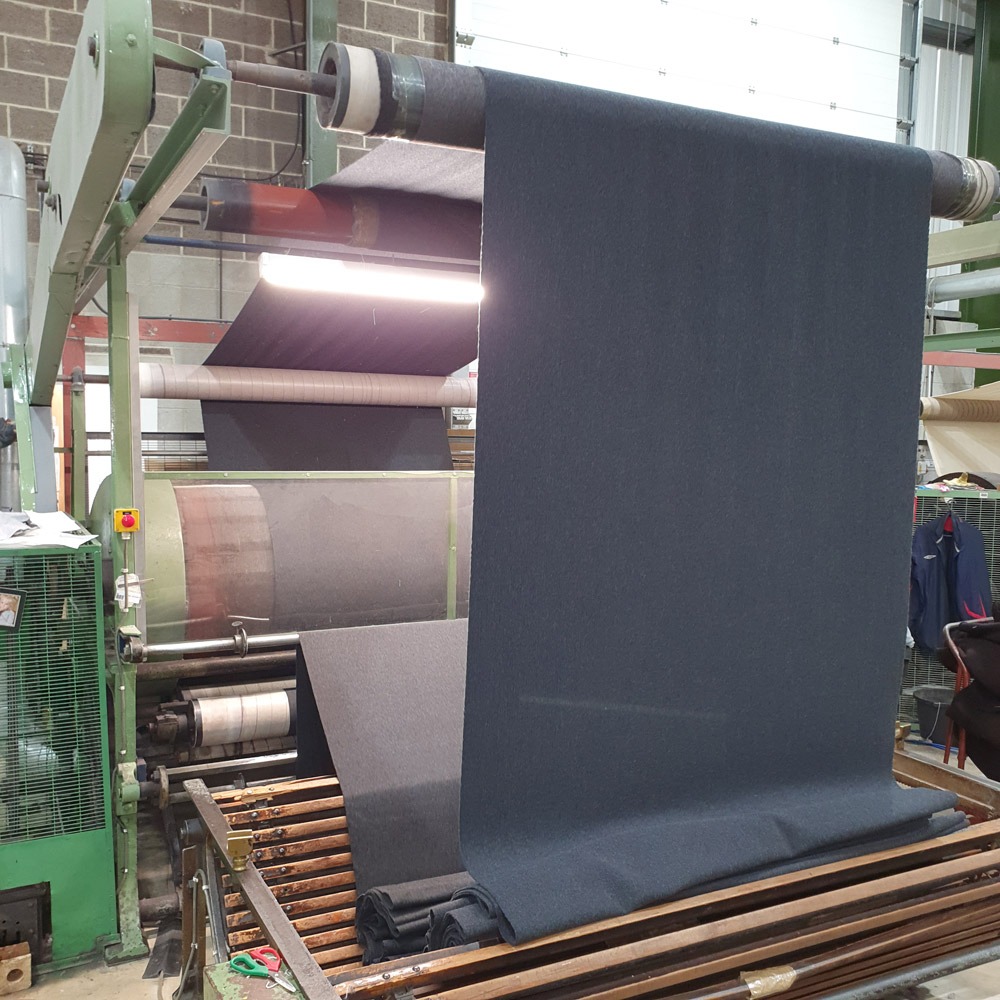

Finishing