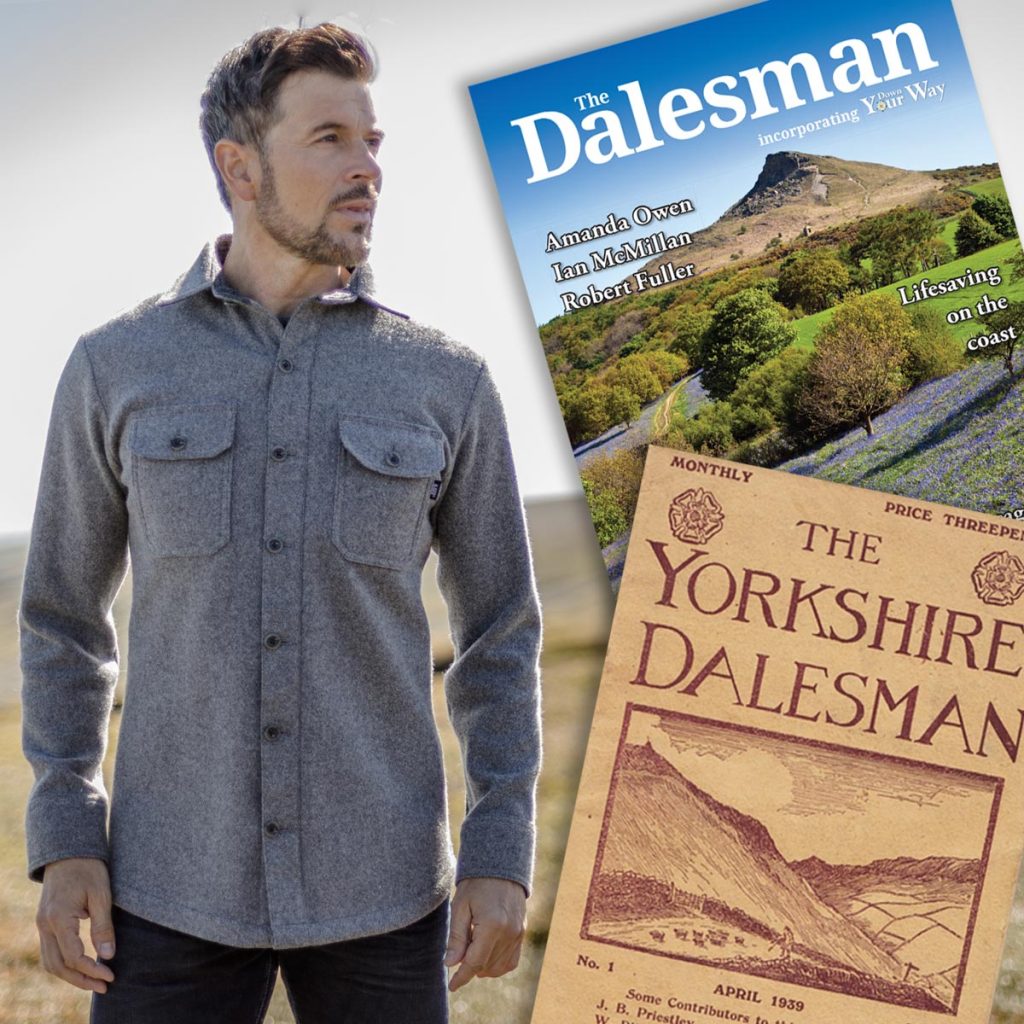

This April we’ve teamed up with The Dalesman to bring you a competition that gives you a chance to win a £300 McNair Gift Voucher. If you’re not familiar with this Yorkshire institution, it was founded in 1939 to celebrate the county’s countryside and people. Over the years great writers such as J.B. Priestley and […]

When McNair set up shop in Slawit, Yorkshire over 8 years ago, we’d never heard of Moonraking – a festival steeped in legend with magical lanterns, storytelling and music to relieve the winter gloom of February. Usually there’s a procession with hundreds of people and thousands of visitors. The whole village would throw open its […]

We’re finally getting to grips with the changes brought about by Brexit – and what it means for our customers in the EU. Over the last few weeks, shipping to Europe has been a little less straight-forward than usual, but we have a plan to make it better. Read on to find out what’s changed, […]

Thanks to all of you who took part in our competition to figure out how we chose the specific colours in our new Charcoal Melange. After several weeks with no correct answers, we then had multiple correct entries. Congratulations to all of you who got the right answer and thank you to all of you […]

It’s unbelievable to think that a year has passed since we embarked on our Provenance Ag adventure with Paul Simons and his team at Glencoe. We have finally started sewing in earnest this month and we think you’ll love the new shirts. And so the cycle starts all over again. Shearing has just finished and […]

Last month we launched our competition on social media asking you how we came to choose the specific colours in our new Charcoal Melange. We have had some very interesting suggestions but so far no correct entries. So we have decided to up the ante and increase the prize fund to £300 for all of […]

The production of our first ever fully traceable merino wool is starting to gather momentum. Next comes the spinning where carded wool is transformed into spun yarn ready for weaving. Here twist is added and the yarn is drawn out to ensure the correct yarn count. You can see the winding process and the preparation […]

Some of you may remember that at the very start of this year a slow boat set sail from Australia with our first supply of merino wool sourced directly from the farmstead. We promised to chronicle all the stages of the production as the beautiful raw merino wool transforms into a McNair Shirt. We are […]

Making from first principles When we set out to make the best Mountain Shirts in the world, we chose Huddersfield as our home. It’s a town that’s been making cloth for over 1000 years. We start with nature’s finest natural fibres and then our town begins its work. The wool is dyed, spun, woven, milled […]

As some of you may be aware, we decided to pretty much close our shirt production in March and shift production to personal protective equipment as there appeared to be an impending shortage. Like many other companies we tried to contact the Covid-19 response team to be of assistance but unsurprisingly in hindsight they were […]